Attention adventure seekers! Are you ready to embark on a hands-on journey and become a Concrete Hero?

Master the Art of Sealing and Refinishing Concrete Countertops

Every craftsman hits a wall. For many in the decorative concrete world, that wall is sealing. It's the quiet stressor behind every project—the final step that can elevate your work to legendary status… or unravel it.

At the Concrete Hero’s Quest, we’re pulling back the curtain on one of the most misunderstood—and mission-critical—aspects of our craft: sealing and refinishing concrete countertops.

This two-day advanced concrete training is built for makers who are serious about leveling up their skills and protecting their reputation. Whether you're working with GFRC or traditional concrete, the principles of proper sealing are universal—and essential.

We’ll walk you through:

Proven sealing systems that hold up in the real world

Step-by-step techniques for refinishing worn or damaged countertops

How to confidently strip failed sealers and breathe new life into old pieces

Troubleshooting tips that can save your projects—and your business

If you’ve ever felt unsure about your process… or you’ve lost sleep wondering if your sealer will hold, you’re not alone. This class is your chance to learn the techniques, the rhythm, and the real-world wisdom that you won’t get from a YouTube video or a Facebook thread.

It’s not just training. It’s the kind of knowledge that separates pros from pretenders—and protects the work you’ve poured your soul into.

Join us. Master the sealer. And step fully into your role as a concrete craftsman.

WHY ATTEND A WORKSHOP AT CONCRETE DESIGN SCHOOL?

Because experience matters.

At Concrete Design School, you learn from working pros, not just instructors. Our team creates high-end custom concrete daily, refining the very techniques we teach. This isn’t about copying a method—it’s about developing your own style and building marketable skills.

Beyond technique, we give you the business tools to price, market, and sell your work successfully. With over two decades of innovation, we don’t follow trends—we set them.

Don’t settle for imitations. Train with the pioneers.

Join a Concrete Design School workshop and experience the difference.

DO I NEED TO BE EXPERIENCED IN CONCRETE TO ATTEND THIS WORKSHOP?

The Concrete Hero's Quest workshop is suitable for attendees of all skill levels, as long as they have a true desire to learn and are driven to create finely crafted concrete. While this workshop is not specifically geared towards beginners, our experienced instructors, Joe Bates (the Master Craftsman), Jon Schuler (The Materials Mastermind), and Brandon Gore (The Godfather of GFRC), will happily answer any questions you may have about the process. Whether you're new to concrete or have been working with it for years, this workshop is a great opportunity to take your skills to the next level and become a hero in the world of concrete. All you need is a passion for learning and a drive to create.

WHAT IS A HERO’S QUEST?

The hero's quest is often seen as a metaphor for the journey of self-discovery and personal growth that an individual may go through in their own life, and typically includes the following steps:

The call to adventure: The hero is faced with a challenge or opportunity that requires him or her to leave the familiar and venture into the unknown.

The departure: The hero sets out on his or her journey, leaving behind the familiar world and entering a new and unfamiliar environment.

The trials and challenges: The hero faces a series of challenges and tests that help him or her to grow and develop as a person.

The inner transformation: Through the challenges and trials of the journey, the hero undergoes an inner transformation and becomes a more complete or whole person.

The return: The hero returns home, often with a newfound sense of purpose and understanding.

We're excited to invite you to join us on the exciting journey of improving your decorative concrete skills and knowledge. This is a one-of-a-kind opportunity to be a part of a community of innovators who are passionate about pushing the boundaries of concrete design and fabrication, and helping you build a successful business. Enroll in this Concrete Design School workshop today and join us on the concrete adventure of a lifetime.

Workshop Dates

Concrete Hero’s Quest: To Be Announced

SESSION TIME AND CAPACITY

2 days of training at Concrete Design School

These sessions are limited to 30 participants to ensure hands-on learning and class participation

Cost

First-time Students: $1,995*

Alumni: $1,395*

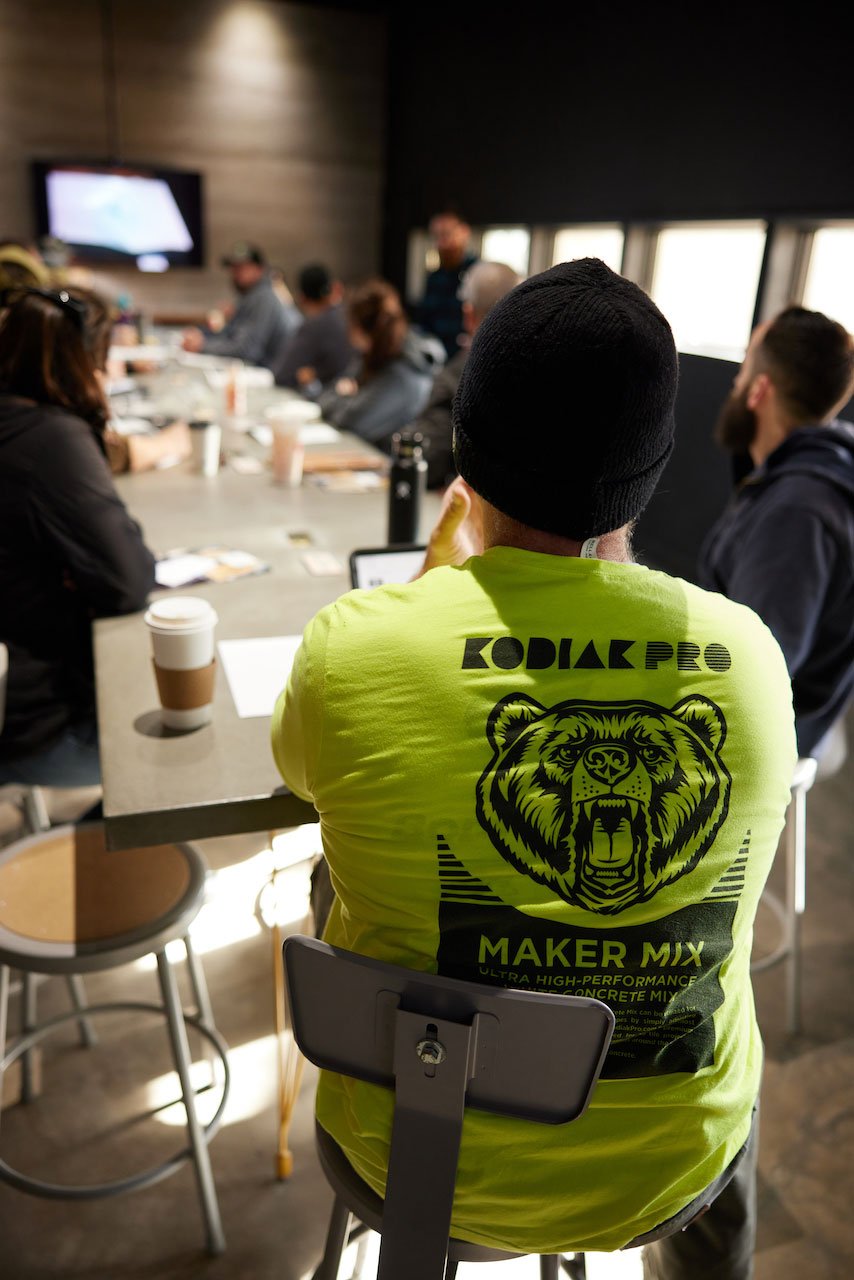

*We're thrilled to share that we've teamed up with Kodiak Pro to provide the materials for this workshop. As a bonus, each attendee will receive a $100 materials credit for Kodiak Pro Maker Mix, RADmix, or Kodiak Pro Diamond Pads compatible with many top brands of sanders, redeemable at a later date. With this credit, the workshop costs effectively decrease to $1,895 for First-Time attendees and just $1,295 for Alumni!

Not sure which ticket type to purchase? If this is your first Concrete Design School workshop, select the 'First Time Student' ticket. If you've attended a Concrete Design School class before, choose the 'Alumni' ticket for discounted pricing as a thank you for your continued support.

PURCHASE TICKETS NOW

WORKSHOP LOCATION

This workshop will be held at:

SC Fabrication

68 Coombs Street, Ste. N-3

Napa, California 94559

InstructorS

The Fine Print

Thank you for considering Concrete Design School for your workshop needs. We understand that sometimes unforeseen circumstances may arise and you may need to cancel your enrollment. If this is the case, we are happy to offer you the option to apply your course fee towards a future Concrete Design School workshop. Please note that we are unable to offer refunds for cancellations.

In order to protect the proprietary information taught during our workshops, all participants will be required to sign a Non-Disclosure Agreement. This agreement includes penalties for unauthorized disclosure of material, and prohibits the publication, broadcast, rewriting, or redistribution of any information learned during the workshop in any form.

We reserve the right to change, modify, or cancel the class schedule at any time. If a change or cancellation is necessary, we will do our best to notify you as soon as possible. Thank you for your understanding.

Glossary of Terms:

Advanced Mold Making: Advanced mold making in the context of precast concrete refers to a sophisticated and specialized process of creating intricate molds with precision and innovation. This technique goes beyond basic mold construction, involving the utilization of advanced materials, cutting-edge design considerations, and refined fabrication methods. The goal is to produce molds that enable the casting of complex and highly detailed precast concrete elements, pushing the boundaries of traditional craftsmanship. Advanced mold making contributes to the production of superior-quality precast concrete products, allowing craftsmen to achieve intricate designs, textures, and finishes in their creations.

AR Glass Fiber: AR (Alkali Resistant) glass fiber is a type of glass fiber that has been treated with a coating of aluminum oxide (Al2O3). This coating gives the fibers increased strength and durability, making them suitable for use in a variety of applications, including reinforcing concrete.

Concrete Hero: A concrete hero is someone who is skilled and dedicated to the art of working with concrete. They are able to create beautiful and functional concrete pieces, and are always looking for ways to improve their skills and push the boundaries of what is possible with concrete.

GFRC: Glass fiber reinforced concrete (GFRC) is a type of concrete that is reinforced with glass fibers. It is often used for decorative concrete projects because it is lighter and easier to work with than traditional concrete, and it can be molded into a variety of shapes and forms. GFRC is also very strong and durable, making it suitable for use in a wide range of applications.

PVA Fiber: PVA (polyvinyl alcohol) fiber is a type of synthetic fiber that is commonly used as a reinforcing material in concrete. It is known for its high tensile strength, low elongation, and good dimensional stability, making it an excellent choice for reinforcing concrete structures.

Post-Tensioned Concrete: Post-tensioned concrete uses high-strength steel to compress and reinforce the concrete. The steel is stretched and anchored at each end of the concrete structure, and then tightened to a specific tension once the concrete has cured. This process creates a much stronger and more durable structure, capable of withstanding heavy loads and large spans.

Ramm-Crete: A groundbreaking technique in concrete casting, Ramm-Crete captures the raw beauty of rammed earth walls with Kodiak Pro RadMix. Crafted by the masterful hands of concrete artisan and rammed earth builder, Brandon Gore, in partnership with the innovative mind of concrete materials pioneer, Jon Schuler, Ramm-Crete melds the strength and adaptability of concrete with the earthy allure of rammed earth. The process entails the meticulous use of Kodiak Pro RadMix, skillfully blending additives and aggregates to achieve the sought-after visual and tactile qualities. Ramm-Crete stands as a testament to the marriage of durability, style, and eco-consciousness, yielding architectural wonders that evoke both admiration and sustainability.

Reactive Sealer: A reactive sealer is a type of concrete sealer that forms a chemical bond with the surface of the concrete. This bond helps to strengthen and protect the concrete, and can also enhance its appearance. Reactive sealers are typically more durable and long-lasting than other types of sealers.

Upright Casting Technique (UCT): Upright Casting Techniques (UCT) is a pioneering approach to concrete craftsmanship, developed by Jon Schuler and Joe Bates, designed for casting high-end concrete projects in place. Unlike traditional methods, UCT allows for a hand-hewn aesthetic—a raw, organic texture that designers covet and can’t be replicated any other way.

Whether used for cast-in-place sinks, furniture, or architectural elements, UCT empowers craftsmen to shape concrete with precision while embracing its natural beauty. This technique isn’t just about making—it’s about creating one-of-a-kind pieces that tell a story through texture, form, and craftsmanship.

UHPC: Ultra-high performance concrete (UHPC) is a type of concrete that is characterized by its extreme strength and durability. It is made using a combination of fine-grained materials, such as cement, sand, and fine aggregates, as well as high-strength steel fibers or other reinforcing materials. UHPC is often used in the construction of bridges, buildings, and other large structures where strength and durability are critical.